- Home

- :

- All Communities

- :

- Industries

- :

- Gas and Pipeline

- :

- Gas and Pipeline Blog

- :

- Digital Field As-Builting with ArcGIS: No Barcode ...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

Part 2 of 4

By Tom DeWitte and Tom Coolidge

Our first blog of this series provided an overview of how ArcGIS Field Maps is the secret sauce for a cost-effective digital field as-builting solution. This is a solution that integrates with a high accuracy GPS antenna and a mobile computing device. If you missed it, you can access it here..

In this blog article, we will divulge how to configure and automate asset data capture. This is a configuration of ArcGIS Field Maps which can be applied to the documentation of both plastic and steel assets across the gas pipe network.

Pipe organizations need to maintain an ever-increasing amount of information about the assets they install into the pipe network. No longer is it good enough to only know the material, size, and installation date. Today’s data management, integrity management, cathodic protection sizing, and hydraulic modeling systems need to know more. Historically the solution to capturing this additional information has been to simply ask field crews and office mappers to manually enter more information. This is not exactly the ideal solution for an organization that needs to operate efficiently.

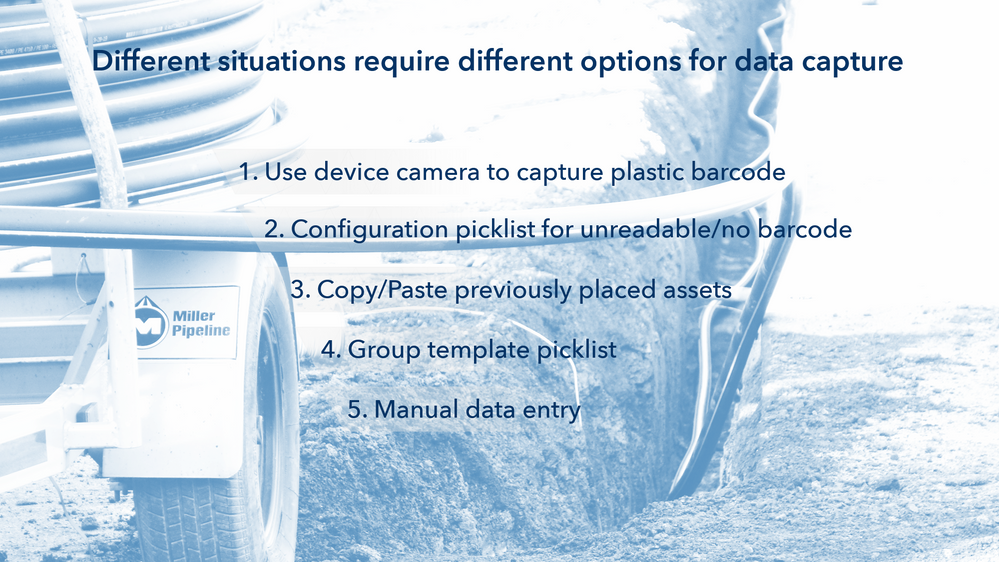

Digitally capturing the geospatial location and characteristics of an asset with sub-foot spatial accuracy and high data quality attribution requires a software application that is capable of a diverse set of data capture methods which all work in a similar workflow. The gas industry is unique across the utility spectrum due to it having industry standards which only apply to a portion of the pipe network. When installing plastic pipe, there is the ASTM F2897 barcode standard. When working with steel pipe, there is no industry barcode format. In a single workday it is not unrealistic to expect that a field crew could be documenting installed plastic pipe with barcode, installed plastic pipe with unreadable barcodes, and steel pipe with no barcodes.

The gas and pipeline construction industry therefore needs a single application with an easy to use interface which is capable of automated data capture for these different situations.

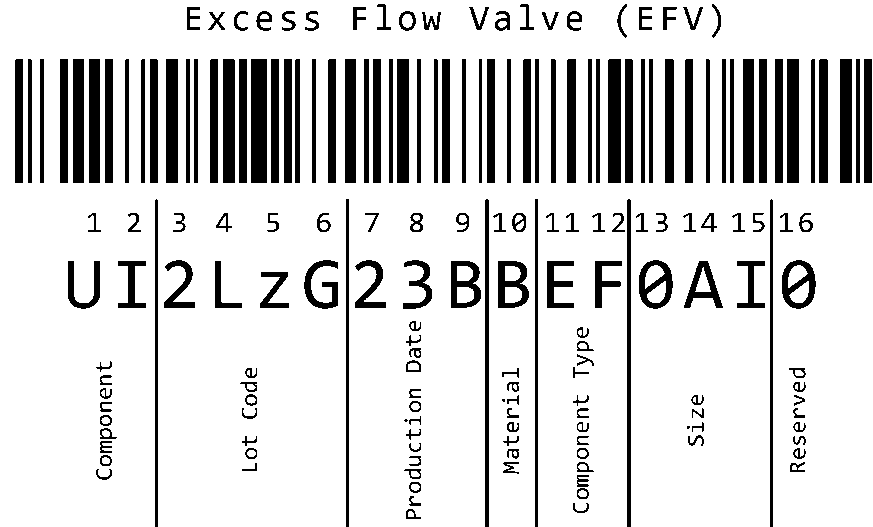

Capturing Plastic ASTM F2897 Barcodes

ArcGIS Field Maps is a mobile application which has seen several enhancements to specifically address the needs of the gas and pipeline industry. This includes the ability to use the mobile device’s camera to easily capture the ASTM F2897 barcode.

Simply point the mobile devices built-in camera at the barcode. As soon as the Field Maps application can successfully read the barcode, it will automatically write the barcode to the designated field. You do not even need to click the photo button!

The second ArcGIS Field Maps enhancement was to be able to run arcade scripts in the pop-up configuration. This allows the barcode information to be immediately decoded and presented to the user. This real-time decoding of the ASTM barcode data even works when the mobile device running ArcGIS Field Maps is not connected to the network.

This ArcGIS configuration for capturing newly installed plastic pipe and plastic components includes server-based scripts called attribute rules to automatically populate the plastic pipe/component data fields. No manual entry of pipe or component characteristics is necessary.

For more on the specifics of this part of the ArcGIS Field Maps configuration, please see the following previously published article; Tracking and Traceability 2019 – Part 2.

Capturing Steel Asset Characteristics

When installing steel pipe or steel components, a different approach is required. Currently there is no industry barcoding standard for steel. So, how can field users avoid manually entering every unique characteristic?

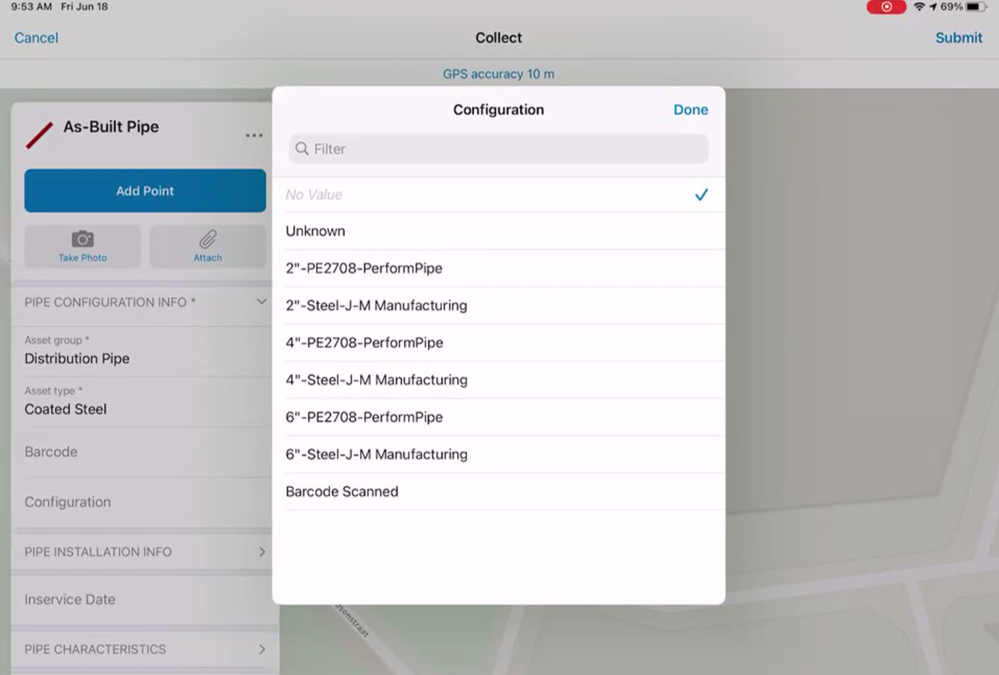

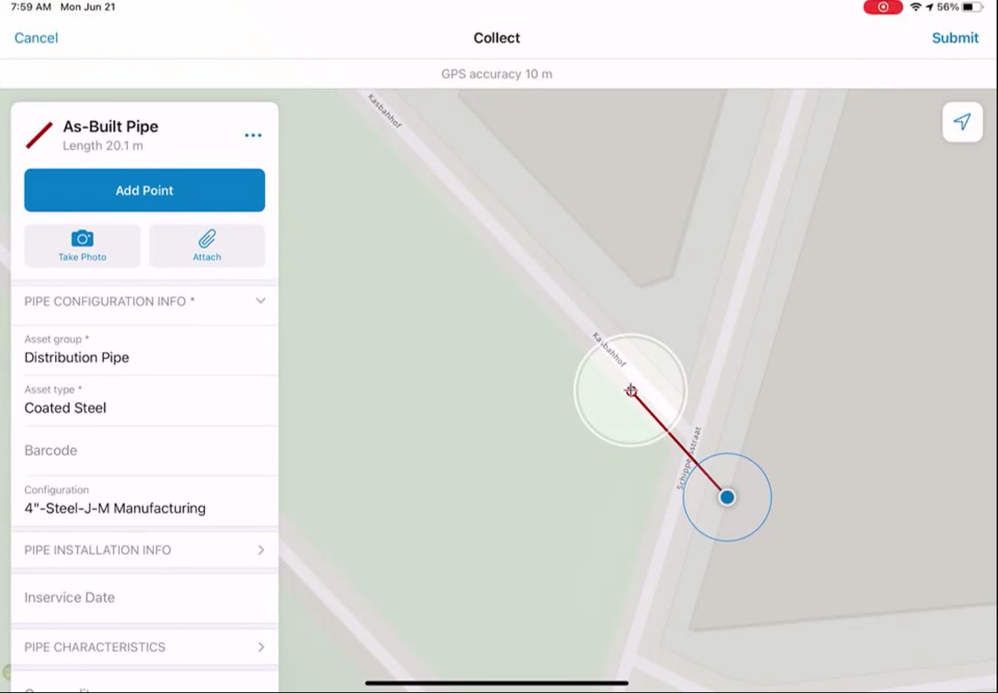

The short answer is to give the field user a list of asset configurations to choose from. This configuration list represents the valid list of sizes, models, and manufacturers the gas organization uses as part of its standards for current pipe system construction. Legacy company configurations, which are no longer used, need not apply. We only want a list of valid configurations for today’s company compliant pipes and components.

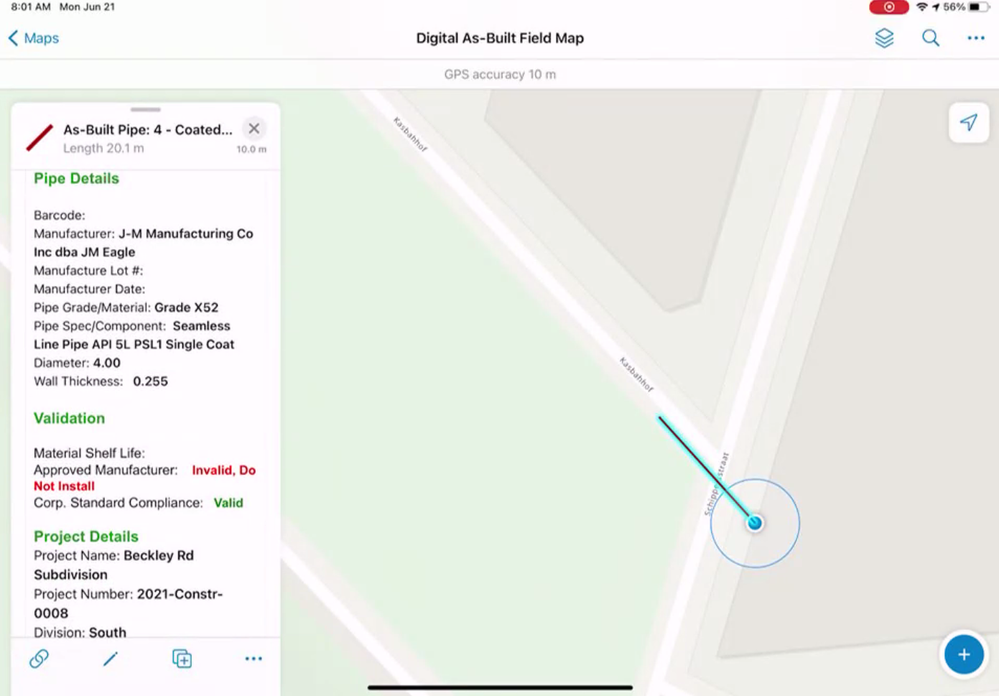

The field user selects the desired configuration from the picklist. ArcGIS Field maps will then read the characteristics of that asset from the look-up table and automatically write the information to the newly installed asset’s data fields. There is no manual entry for the field user. It is a simple matter of selecting a configuration from a picklist. The software will do the rest.

Implementing this capability not only addresses the issue of how to enable field users to quickly and accurately document the characteristics of newly installed steel pipe or a steel component, this same configuration can be used for situations where the plastic barcode is unreadable due to being smeared, scratched, or otherwise obscured.

To deploy this part of the solution requires the following:

-Picklists (Subtype specific coded value domains)

-Lookup tables containing the characteristics of a specific configuration

-Scripts (Attribute rules) to automatically populate the asset’s data field with the configuration characteristics

Need a List

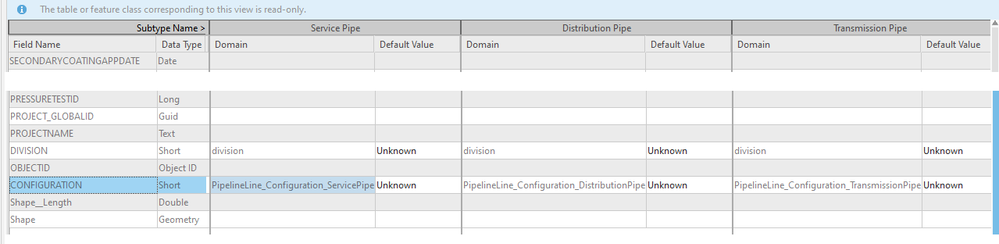

The picklist is defined with subtype specific coded value domains. This simplifies the field user experience by shortening the list of configurations to those which apply to a specific type of asset. Service Pipe, Distribution Pipe, Couplings, Elbows, and Controllable Valves are each separate coded value domains.

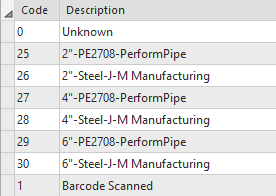

The domain is defined as a field type of short integer. The short integer value is the primary key to the configuration lookup table. The coded domain description is the text which you want the field user to see in the picklist.

Configuration Look-Up tables

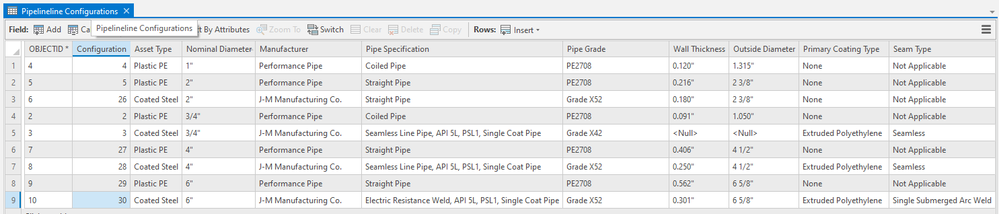

With the subtype specific coded value domain now defined, there needs to be a source which contains the characteristics (pipe diameter, material, manufacturer, wall thickness, etc) for each configuration.

This lookup table is a standard geodatabase table. It must reside in the same enterprise geodatabase as the staging layers which will store the field captured assets.

To simplify the integration with the staging featureclasses and the final production featureclasses, the schema of this table should match the data fields into which this information will be inserted.

Automated Data Entry

Attribute rules are the scripts which provide the automation logic to read the user specified configuration value. The selected configuration code value is then used to query the configuration table to retrieve the asset’s characteristic information. With the asset characteristic information retrieved, it can then be written to the appropriate data fields of the same record from which the user selected a configuration type.

//Rule Name: StagingPipelineLine_Configuration

//Description: Set multiple fields based on Configuration value

//Subtype: All

//Field: Leave blank. Setting multiple fields.

//Editable: unchecked (false)

//Trigger: Insert, Update

//Error Code: 72

//Error Message: Couldn't set values based on ConfigurationID

//Evaluate from application evaluation: checked (true)

//Get Configuration ID value

var configurationId = $feature.configuration;

if (configurationId == null) {

return;

}

// If update operation, only fire if configuration value changed

if ($editcontext.editType == 'UPDATE'){

if ($originalFeature.configuration == $feature.configuration) {

return;

}

}

//Query Configuration_Lines table for configuration

var cuTable = FeatureSetByName($datastore, 'Configuration_Lines', [‘assettype’,'nominaldiameter','manufacturer','pipespecification','pipegrade','wallthickness','outsidediameter','primarycoatingtype','seamtype’], false);

//Use the first record returned from the query

var cuAttribute = First(Filter(cuTable, 'configuration = @configurationId'));

if (cuAttribute == null) {

return;

}

else {

return {

'result': {

'attributes': {

'assettype': cuAttribute.assettype,

'nominaldiameter' : cuAttribute.nominaldiameter,

'manufacturer' : cuAttribute.manufacturer,

'pipespecification' : cuAttribute.pipespecification,

'pipegrade' : cuAttribute.pipegrade,

'wallthickness' : cuAttribute.wallthickness,

'outsidediameter' : cuAttribute.outsidediameter,

'primarycoatingtype' : cuAttribute.primarycoatingtype,

'seamtype' : cuAttribute.seamtype

}

}

};

}

When these three configurations are added to ArcGIS Field Maps, the field user experience is simplified. The user selects the configuration from the picklist, such as 4” Steel by J-M Manufacturing.

The software runs the script, which retrieves the configuration information from the look-up table, and inserts it into the new record.

The pipe record now has its characteristics automatically populated. No barcode, no problem.

Documenting New Construction Requires Adaptability

This ability to use the advanced configuration capabilities of ArcGIS to address the issue of how to capture pipes/components with no barcodes demonstrates how important adaptability is to a digital field as-builting solution. Just like gas and pipeline industry field crews are constantly adapting to unexpected issues during construction, a digital field as-builting solution needs to provide a wide range of data capture capabilities to overcome unexpected construction documentation issues. The adaptability of ArcGIS Field Maps extends beyond the previously described ability to scan plastic ASTM F2897 barcodes, and to select a pre-defined configuration from a picklist when no barcodes are available. It includes the ability to copy the information from a previously placed and documented asset. Lastly, there is always the ability to manually enter the asset characteristics. Even in this last option, there are still picklists to help the field user to quickly and accurately enter this information.

This blog article is the second in a series of four blogs articles explaining how to deploy ArcGIS Field Maps for Digital Field As-builting. Next blog article will divulge the secret sauce of configuration and automation for simplifying the documentation of pressure tests.

PLEASE NOTE: The postings on this site are our own and don’t necessarily represent Esri’s position, strategies, or opinions.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.