- Home

- :

- All Communities

- :

- Industries

- :

- Gas and Pipeline

- :

- Gas and Pipeline Blog

- :

- Pipe Risk Analysis Is Spatial

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

By Tom DeWitte and Tom Coolidge

What keeps pipe network utility executives up at night? One common cause is the worry about the consequences of a failure that results in negative impacts to people, property, or the environment. One-way utilities pro-actively seek to pre-empt pipe network failures is investment in repairing or replacing those parts of their network thought most likely to possibly fail.

Every year utilities determine which sections of their pipe system will be replaced as part of their capital construction budget. How do utilities know which sections of the pipe system need to be replaced? What are the criteria that should be used to identify and prioritize the sections of pipe for replacement?

To many pipe engineers, the answer is to perform a pipe risk analysis.

Pipe risk analysis is a method of identifying criteria which will be used to rank which sections of pipe should be replaced. These criteria are quantified and weighted against each other using an equation to tally the total risk score for each section of pipe.

What criteria do you use to measure risk? When dealing with pressurized pipe systems, such as natural gas, hazardous liquids, district energy, and water the initial criteria list typically starts with these items:

-pipe material

-pipe age

-pipe installation method

-pipe insulation/coating materials

-leak history

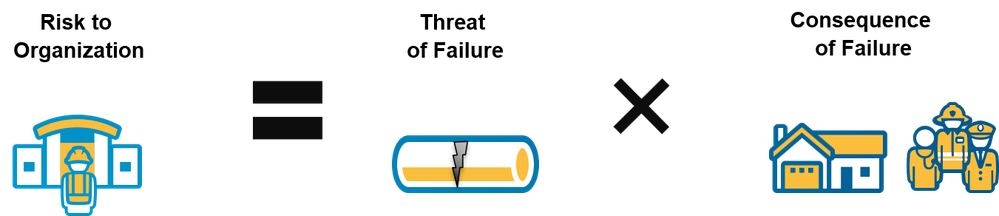

These items are valid criteria that contribute to the likelihood a pipe system may fail. These types of data are easy to put into a spreadsheet and tabulate. But none of these measures the consequence of those failures and the risk to the organization.

Understanding the risk to the organization can only be accomplished by including a measurement of the consequences.

Understanding Risk to the Organization

Risk to the organization is typically summarized as a cost, with the unit of measure being monetary ($). This cost is much more than simply the expense to the utility to have the construction group replace the identified deficient section of pipe. When a pipe section fails, it impacts the people and facilities near the location of failure.

This consequence cost to the organization often greatly exceeds the cost to replace. The recent situation of Pacific Gas & Electric declaring bankruptcy after the involvement of its electric transmission lines in forest fires is the exclamation point example. Every pipe utility industry has multiple examples they can point to which validate that the consequence cost of a failure greatly exceeds the cost to replace. Property damage, loss of life, loss of business revenue, civil lawsuits, and government regulatory fines are just of few of the consequences of failure and its resultant cost to the organization.

To measure the risk to the organization, we need spatial tools

Quantifying the consequence of failure begins with understanding “where.”

-Where are the properties and facilities nearby pipe segments?

-Where are the persons who reside or congregate near the pipe segments?

-Who are the customers downstream of the pipe segment who will be impacted by the failure?

Understanding the relationship between your pipe sections in relation to critical facilities, persons, and customers, requires spatially aware-analysis tools.

Spatially aware tools, such as those provided with Esri’s ArcGIS products, enable pipe utilities to identify, aggregate, calculate, and quantify these consequences.

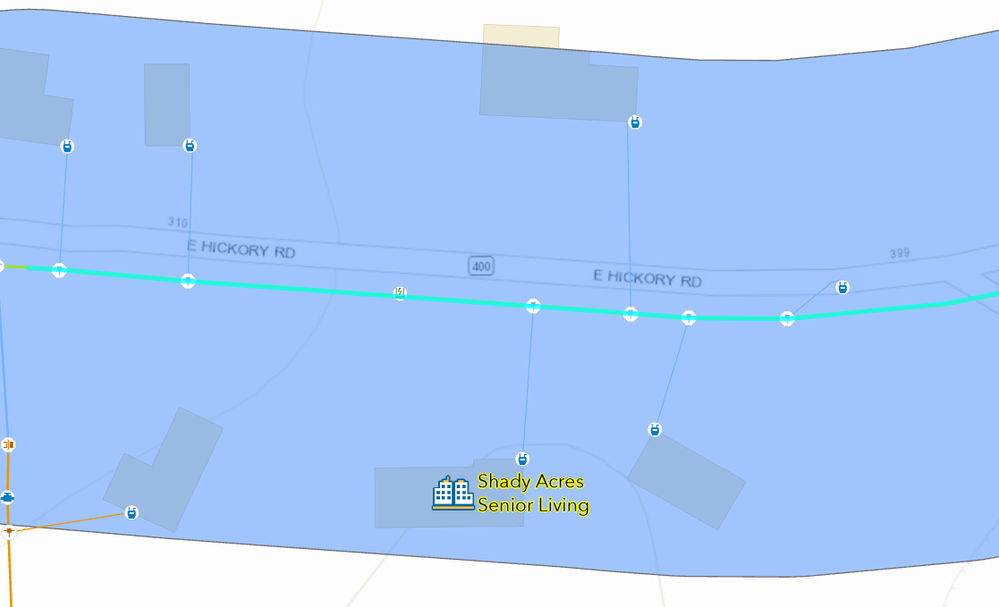

Understanding Who is Nearby

Every person who resides or congregates near a pipe section is at risk of being impacted by the failure of that pipe section. As stated previously, this is key to quantifying the overall risk to the organization. Spatial analysis methods, such as buffer, can define the area near the pipe segment to look for persons and places of gathering.

More advanced spatial analysis methods, such as least cost path analysis, enable pipe utilities to identify the direction in which spilled liquids will flow. Once these spatial areas near the pipe segment are identified, it is a simple intersect analysis against data sets which identify the number and type of persons who reside or congregate within the now identified areas of impact.

With this analysis capability, pipe utility organizations can quantify the consequence of the failure of a pipe segment to persons.

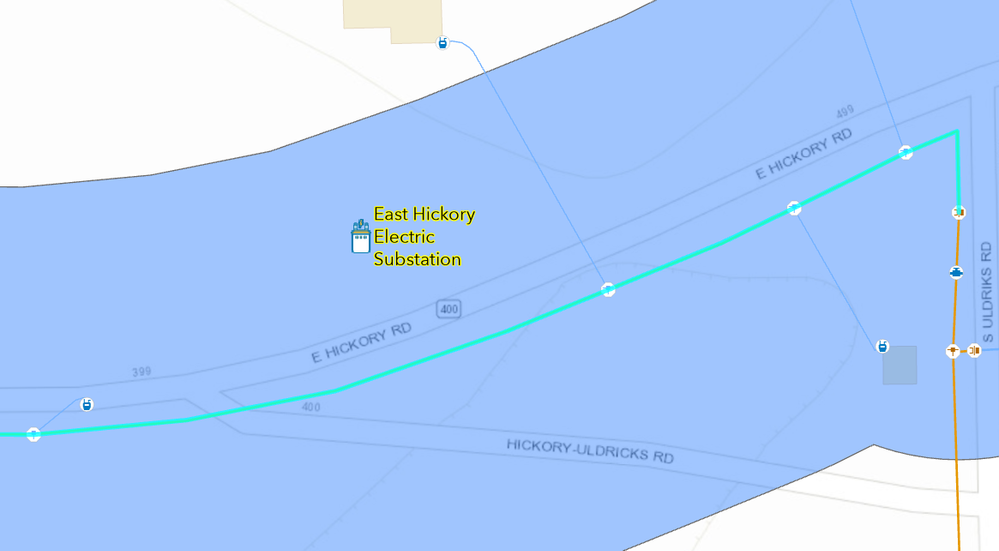

Understanding What is Nearby

The cost to the pipe organization of the failure of a pipe section includes not only the impacted persons, but also the impacted facilities. Having your own facilities damaged is bad enough, but also having to pay to repair the facilities of other utilities can be much more expensive. Understanding the consequence of failure to facilities goes beyond electric, telecommunications, and other pipe utilities, it includes transportation network systems such as road and railroad. No pipe utility wants to be the one that caused a major road route to be closed due to the damage caused by the pipe section failure.

The same ArcGIS analysis tools used to identify persons impacted by a pipe section failure (Buffer, Least Cost Path, Intersect, Identity) are the tools used to identify and quantify what facilities are impacted.

This understanding of the consequence of failure to nearby facilities further clarifies the true risk to the organization. But there is still one more critical consequence to be understood and quantified. That is the consequence to the pipe utilities customers who are downstream of the pipe section which has failed.

Understanding Customers Downstream

When a pipe section fails, customers downstream of that point of failure will be without the transported commodity until repairs are completed. This means that natural gas and district heating customers could be without heating in the middle of a winter deep freeze. District cooling customers could be without air conditioning during a summer heat wave. Both consequences of failure can literally result in death to customers.

Programmatically understanding and quantifying the impact to a pipe utility’s customers requires a different set of spatial analysis tools. These different spatially aware analysis tools need to understand how the pipe network of pipes, valves, and fittings connect to create a pipe network. Only when a software application understands how a commodity flows through the pipe network can the analysis quantify the consequence of failure to the customers.

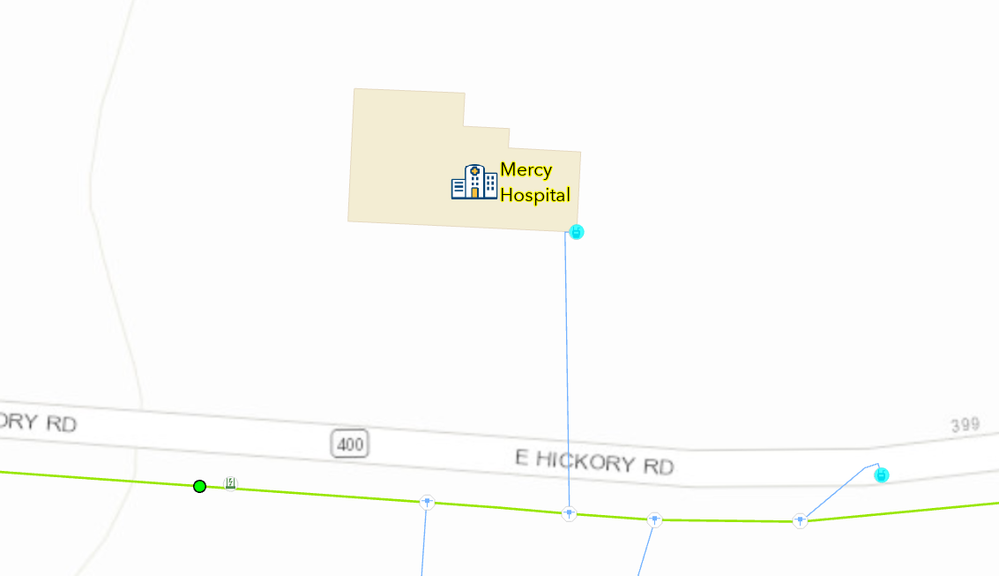

This pipe network aware tool which is critical to measuring the consequence of failure to customers is the downstream trace. The downstream trace is a configuration of the Trace tool provided with ArcGIS Utility Network.

With this type of spatially aware analysis, it is now possible to quantify how many critical facilities such as hospitals, senior living complexes, refineries, power generation plants, and major manufacturing facilities are impacted by the failure of a pipe section.

It’s a Spatial Thing

Understanding the total risk to a pipe organization requires spatial awareness. This spatial awareness empowers pipe organizations to improve their capital improvement plans. Engineers leveraging spatially aware tools such as those provided with ArcGIS can quantify the multiplier impact consequences have on threats of failure. Knowing how your customers will be impacted by a pipe section failure is another type of spatial analysis that is also key to measuring risk to the organization.

As you can see, pipe risk analysis is spatial.

PLEASE NOTE: The postings on this site are our own and don’t necessarily represent Esri’s position, strategies, or opinions.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.