- Home

- :

- All Communities

- :

- Industries

- :

- Gas and Pipeline

- :

- Gas and Pipeline Blog

- :

- Preventing Damage Through Better Data

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

By Tom Coolidge and Tom DeWitte

Earlier this year, I was walking down a street in mid-Manhattan. During the walk I noticed a surprising amount of steel plates covering active excavation projects under the streets and sidewalks. There were also many open trenches which exposed an amazing number of pipes and wires. Not being from New York City, I was surprised at the shear volume and complexity of buried infrastructure. This got me to pondering about recent gas events and the questions an organization asks itself.

-Could the damage to the pipe system have been prevented?

-What organization processes could have performed better to prevent the damage?

This leads to an organization self-examination of processes to determine where improvements need to be made. These self-exams are important and valuable, but they are also reactive.

Typical reactive questions which are commonly asked include:

- Did the locator group correctly mark the location?

- Was the locator provided with accurate and timely information to assist with the locate?

- Were the correct engineering and construction documents provided?

These reactive self-exams often overlook a root cause: inaccurate data gathering methods.

The American Gas Association recently published a white paper titled “Implementing Damage Prevention in Field Operations.” The white paper can be accessed at:

Included in the white paper is a section on “Mapping/As-Builts” that resonates with important aspects of the role of geographic information systems (GIS) in gas utilities. This blog touches on those important aspects.

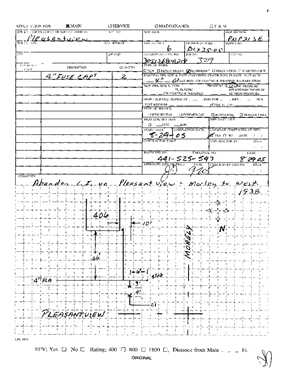

Inaccurate data gathering with relative offsets

The AGA whitepaper allocates two of the nine sections to address the importance of data gathering techniques around the construction and mapping/as-built processes for documenting “where” the pipe components were installed. Inaccurate data gathering methods have persisted in the gas industry since its founding. In early gas company days, locating a buried pipe was based on “relative offsets”. A relative offset is a measurement from an identifiable above ground feature to the location of the buried pipe asset. It was not uncommon to see measurements, such as 45ft NNE of the Old Oak Tree. But what happens when the tree falls over after a storm and is removed?

Later relative offset techniques switched to using street curb edges or house corners, such as 12ft South of the North curb. This too is subject to change over time. How accurate is this measurement when an additional lane is added to the north side of the street?

As pointed out in the previously mentioned AGA white paper, these methods are inaccurate over time. Yet, many in the industry are still using these centuries-old methods to document the location of newly installed pipe.

How to proactively prevent damage

Now there is an opportunity to be proactive. To use current cost-effective data gathering tools such as Global Positioning System (GPS), lightweight digital collection tools such as mobile phones and tablets, and data management systems such as GIS. This allows the location of buried assets to be based on its absolute location instead of its relative location. Using absolute location eliminates the historical issues of relative features changing over time.

An opportunity to improve

Today’s gas organizations are undergoing a massive capital improvement process to replace or abandon many old and inaccurately mapped gas pipe components. This increase in capital projects provides the opportunity to accurately locate new infrastructure and decrease future damages. Gas organizations can update data gathering methods to cost-effectively collect new construction with a sub-foot absolute accuracy. They can implement a geospatial system that is capable of electronically collecting and storing this information. Future engineering, construction, and locate organizations will have the confidence in knowing that their mapped pipe components are spatially accurate and reliable.

If you haven’t already read the recently published AGA white paper, we encourage you to do so. It’s well worth your time. There are many other points worth noting.

The next time I visit a major city and again see the steel plates and excavation pits, I hope to have the confidence in knowing that the local gas organization has been proactive and is using current data gathering tools and techniques to prevent future damage.

PLEASE NOTE: The postings on this site are my own

and don’t necessarily represent Esri’s position, strategies, or opinions.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.